Very different properties are required of machine components. To meet these

requirements, a wide range of ceramic materials with very different properties has been developed.

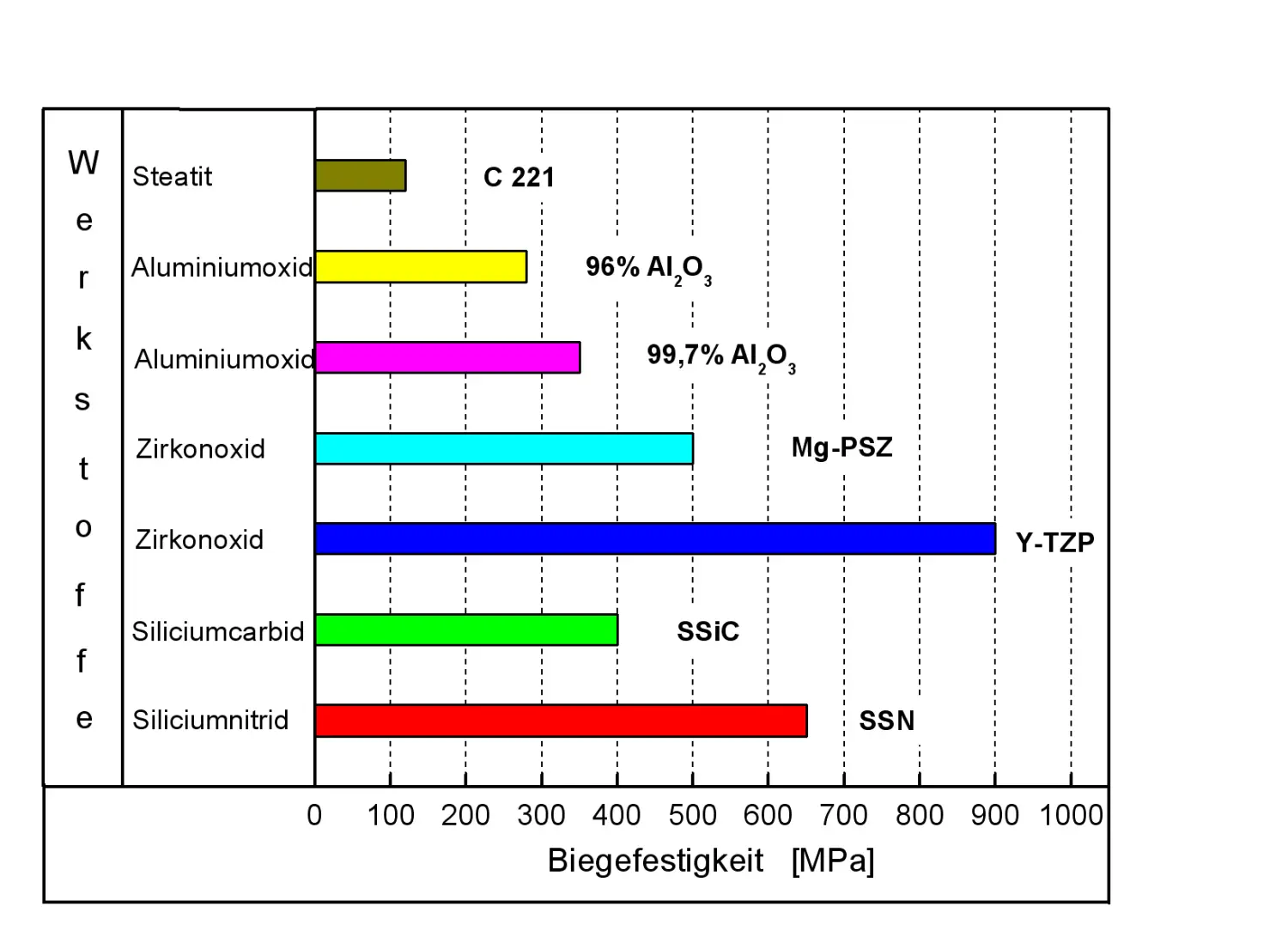

The high mechanical strength of the ceramic materials predestines them for use in

equipment and mechanical engineering.

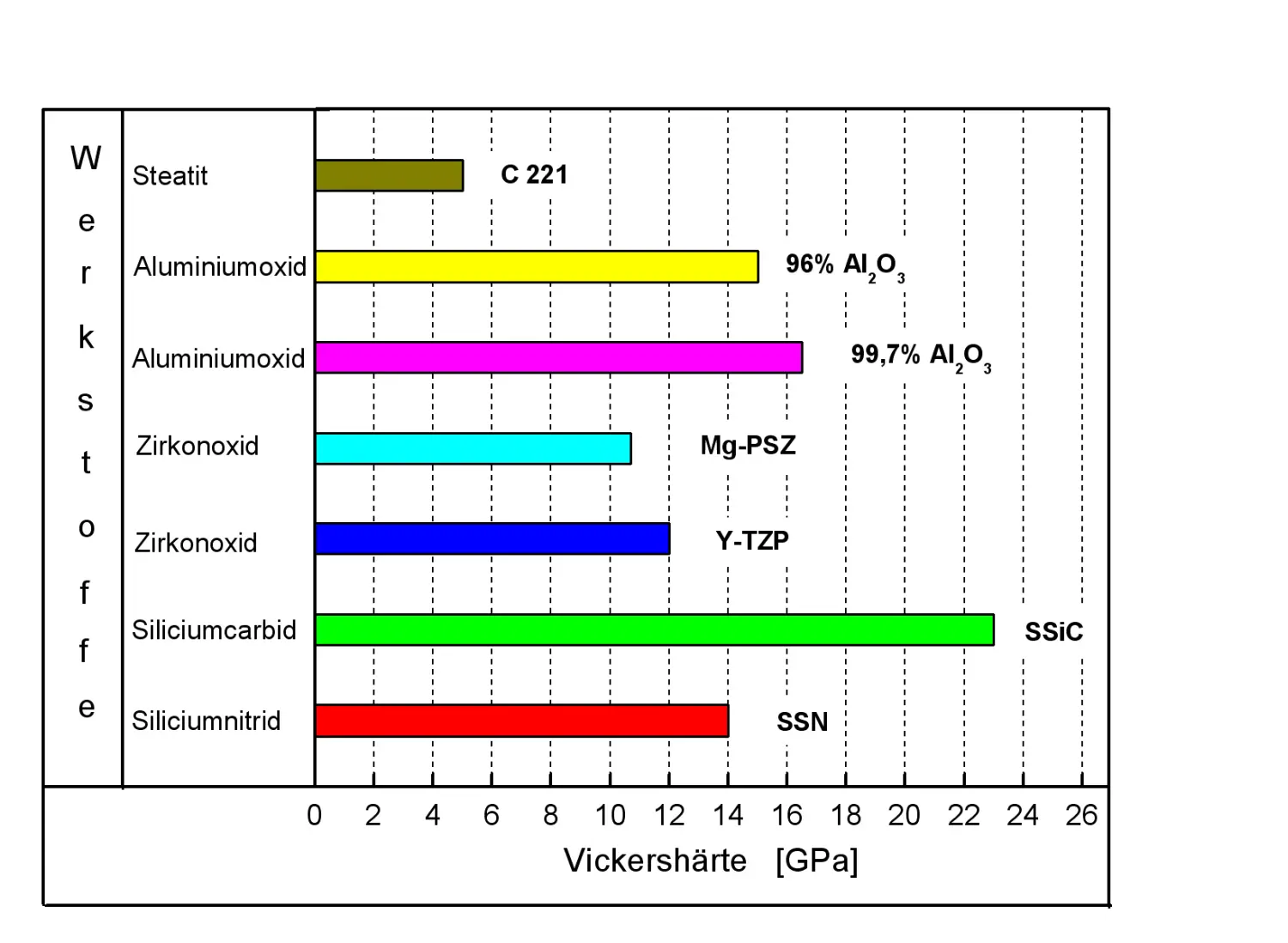

The hardness of advanced ceramic materials is inferior only to the hardness of diamond and

is much higher that the hardness of steel. For this reason, ceramic materials are excellent

suitable to produce abrasion-resistant components e.g. for the paper-, textile-and wire

industry.

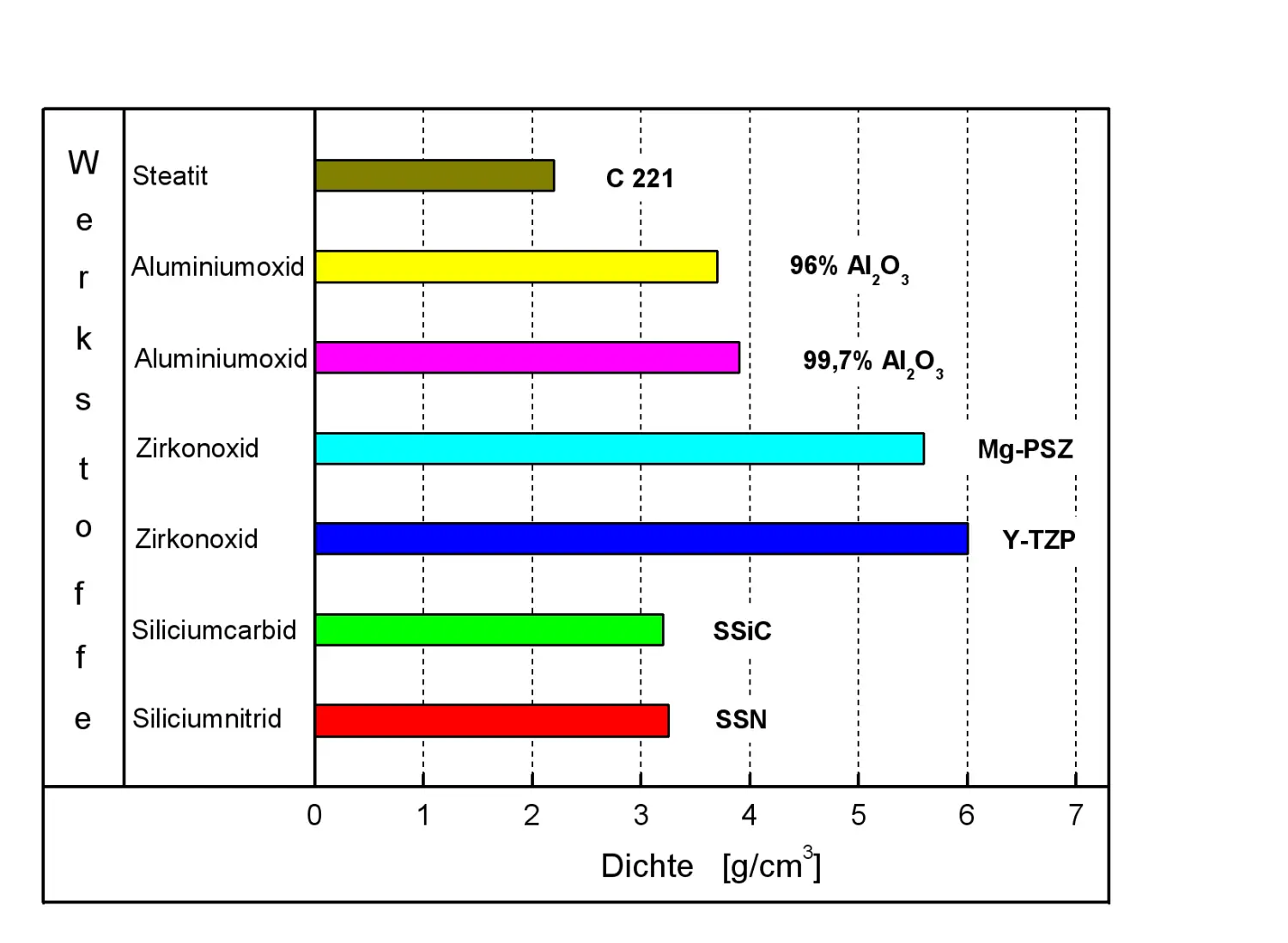

The low density of ceramic materials is advantageous in the design of moving and rotating

components such as bearings, valves and rotors.

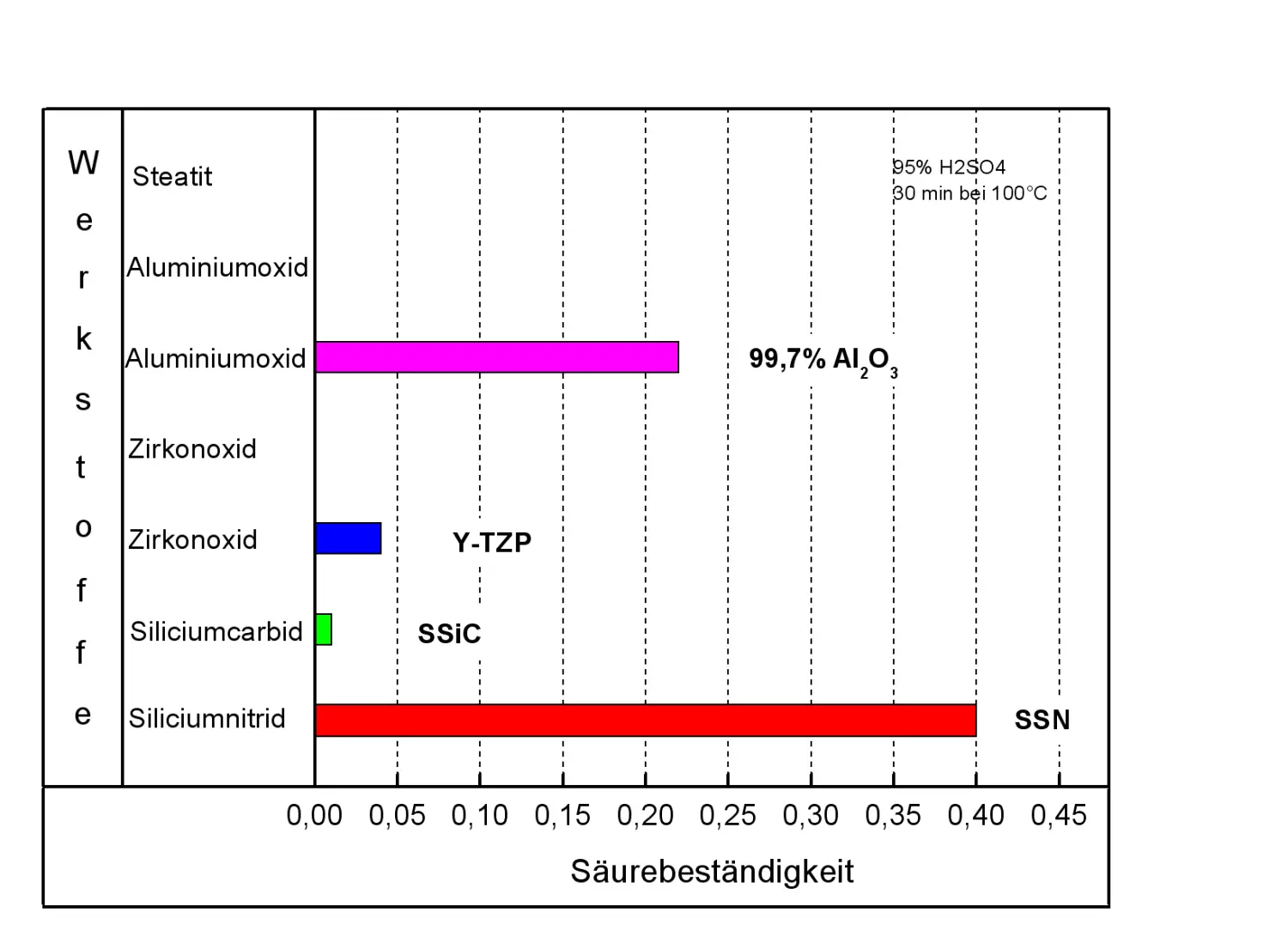

In contrast to metals ceramic materials react only slightly with alkaline and acids. They are

therefore ideal for the application in chemical industry.

Moreover, ceramic materials are bioinert and are used as implants (e.g. hip joint

endoprosthesis, tooth pins, malleus) in the human body.

All ceramic materials (including non-oxides) exhibit excellent oxidation resistance at high

temperatures.

Ceramic materials are extreme heat-resistant. Metals lost their properties above 500 °C. In

Ceramic components, on the other hand, can also be used above 1000 °C, for example in

metal industry in direct contact with molten metals (e.g. pulling rings).

For the property values given in the diagrams, the preliminary remark to DIN EN 60672-2 a

applies mutatis mutandis, according to which the values communicated apply only to the

samples on which they were measured. A transfer to other geometries is only permitted to a

limited extend. The values given are therefore only to be regarded as a guide values.